Can I have a test chamber? ....These are the questions we will ask you.

Simultech believes that when we supply a test chamber, it should suit our customer’s testing needs, while our customers know their products, its unusual for them to know test chambers and the many factors that influence the performance of a test chamber. Simultech’s 20 years of experience with test chambers and the experience that this provides is one of the benefits of working with Simultech.

Below are a series of questions that we will typically ask when trying to understand your exact requirements.

Common questions include:

2. What are the exact temperature and humidity points you wish to perform tests at?

6. Are there cables connected to your product and how do you wish them routed out of the chamber?

7. How do you plan to orientate the specimen within the test chamber?

8. Can the product be damaged by overheating?

9. Does the product contain explosive materials within it such as solvents or batteries?

10. Is hazardous condensate produced by your test?

11. What power do you have available?

1. What testing do you wish to perform, are you testing to a standard? Could you provide us with a full test profile?

We may be asked to provide a quote for a 340L climate test chamber capable of operating between -40 to 180 deg C and with a relative humidity range of 10-98%. While this is a good start it doesn’t give us all of the information that is required to offer the best solution. For instance, is there a desired temperature ramp rate, is there a requirement to conduct low temperature and low humidity testing ie 10 deg C and 20% RH, is there a requirement for high humidity testing?

If our customer is able to provide their planned testing profiles or test standard and indicate which part of the standard they need to meet we can review this and determine which chamber will satisfy all of their requirements.

2. What are the exact temperature and humidity points you wish to perform tests at?

If a test profile or test standard can’t be provided then providing as much information about the tests to be conducted is critical. For instance a low temperature and low humidity test say 20 deg C and 10% relative humidity would require a low dew point to be created by the chamber and would require the use of an optional air dryer to achieve this dew point.

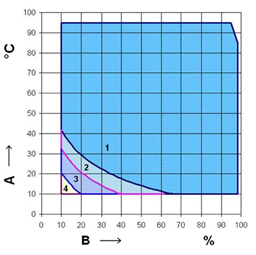

Below is a typical climate chart for a ClimeEvent test chamber.

The coloured sections indicate what temperature and humidity can be achieved with this chamber.

Section 1: Is the standard climate range

Section 2: Standard climate range for discontinuous operation only (dew points ranging from +4 °C to -3 °C)

Section 3: Extended climate range with dew point temperatures controlled up to -12 °C using dried compressed air

Section 4: Extended climate range with dew point temperatures controlled up to -20 °C using dried compressed air and capacitive humidity measuring system

Using the above chart as an example the chamber can continuously operate at a temperature of 40 deg C and a humidity of 10% and can operate for several days at a temperature of 10 and 40% RH. However, should you wish to perform testing at 10 deg C and 10% RH you would need the optional -20 deg C Dried Compressed Air System.

As another example the chamber can continuously operate at a temperature of 10 deg C and a humidity of 65% and can operate for several days at a temperature of 32 and 10% RH. However, should you wish to perform testing at 10 deg C and 10% RH you would also need the optional -20 deg C Dried Compressed Air System.

3. Is the temperature ramp rate required based on the temperature of the specimen or the air temperature in the chamber?

If you can provide us with a test profile then we can determine what the required temperature ramp rate will need to be. While the majority of our test chambers have a temperature ramp rate of 3 K/min or greater, if your test profile requires a rapid ramp rate such as 20 K/min ramp rate, then we’ll need to offer a chamber with greater heating and cooling capacity.

We also need to know whether the ramp rate is based on the air temperature in the chamber or the actual specimen temperature as this can vary significantly depending on the composition of the test specimen.

All of our test chambers have been tested to IEC 60068-3-5 which quantifies the internal air temperature ramp rates of the chamber. But, should the ramp rate be based on the specimen then this adds a significant level of complexity. Everything from specimen composition, size, shape, quantity to be tested in the chamber at once and their position within the chamber can effect the temperature ramp rate of a specimen. While this is incredibly difficult to quantify, our years of experience can assist in ensuring that the chamber we provide will satisfy your ramp rate requirements.

4. What are the dimensions, weight and materials used in your product?

Another important question when determining the internal test volume of your chamber, if the test volume isn’t large enough then there will be insufficient air circulation around your product and heating and cooling can be compromised. Typical the test chamber's internal volume should be three times that of your test specimen.

A test chamber that is too small to properly fit your specimen, will have compromised heating and cooling rates and will suffer from poor air circulation meaning that your specimen won’t be heated or cooled uniformily.

If there are multiple specimens in the chamber, how they are placed in the chamber to achieve the best air flow around them is crucial. Improper placement of specimens such as placing them infront of other specimens can cause air flow to them to be blocked, meaning that some test specimens may heat or cool faster than others.

Specimen shape also influences its heating and cooling rate. The shape of products is crucial to the lag time between the change in temperature between the internal temperatue of the test chamber and the product.

Weiss Technik regularly perform a wide variety of tests in their chambers to quantify their performance, One such test examined the impact that the shape of an object had on its internal temperature Various specimens of the same material and weight were tested:

- A Rectangular cuboidal shaped product had an internal heat change of 3.6 kelvin per minute with an exterior increase of 22 kelvin per minute

- A Cylindrical product had an internal heat change of 8.2 kelvin per minute with an exterior increase of 19.2 kelvin per minute.

- While a Sheet shaped product had an internal heat change of 11.5 kelvin per minute with an exterior increase of 16.4 Kelvin per minute.

5. Will the specimen be powered on or off during testing and if on, what is its heat load during the various parts of the test?

Its important for us to know whether your product is turned on or off during testing and if turned, when will it be turned on on what is the heat load generated by it.

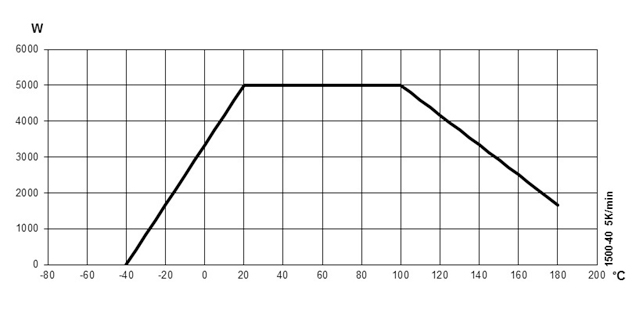

Below is a Heat Compensation Chart from a ClimeEvent 1500 litre -40 to 180 deg C, 3 K chamber.

If the chamber is operating between 20 to 100 deg C, then the chamber is capable of operating normally and removing a heat load up to 5000 Watts. However, as the temperature decreases below 20 deg or increases above 100 deg C, its ability to remove the heat load from your product is decreased. For instance at -40 deg C, no heat load can be removed, therefore if your product generate heat then a different chamber will need to be offered such as a -70 to 180 deg C chamber.

This Heat Compensation Chart will vary from chamber to chamber.

The above chart is only valid for temperature testing, the heat load will be significantly less for full climate testing and can be as little as 500 watts.

6. Are there cables connected to your product and how do you wish them routed out of the chamber?

Its important for us to know whether you have power or test leads connected to your specimen and how they are connected, the type of cables and where they will need to exit the test chamber. All test chambers come fitted with two flanges, one on each side and sealing plugs for routing of your cables, additional flanges can be ordered if a single flanges isn’t sufficient.

In testing where ramp rates are important, its important for us to know the number of cables, mass and even the composition of these cables to ensure that the test chamber will have a sufficient heating and cooling ramp rate.

7. How do you plan to orientate the specimen within the test chamber?

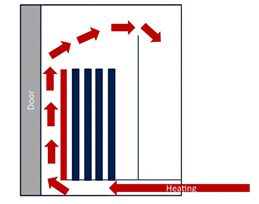

The correct orientation of products when inside the test chamber can be important to a successful test. Products need to be positioned so that air flow to other specimens is not blocked by another. Air should flow equally around each of the products. For instance, the incorrect orientation of a product can lead to it receiving a majority of the heated air causing it to heat more than another product located behind it. This can cause the test to be inconclusive it could also lead to damage to the product at the front due to it being over heated.

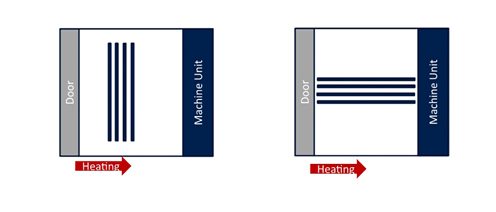

Below are two examples of how four large plates could be placed within a test chamber.

The red arrows indicate the direction of air flow in a Weiss Technik Test Chamber, the image indicates that by placing the plates in the first orientation, then the first plate will be heated more rapidly than those behind it, this can lead to issues with the test. Therefore the second of the above two configurations would be better.

8. Can the product be damaged by overheating?

The prevention of products overheating during a test is essential, the Weiss Technik test chambers come with three levels of over heating protection ranging from electronic controls to a thermal fuse. .During installation our technician can setup temperature limitors within the chamber to prevent this from happening.

Overheating of your product could result from a number of reasons.

- Errors in programming of the chamber.

- Incorrect positioning of your product, if you are testing multiple products at once then positioning a product in front of others may result in the product in the front receiving more heat than those at the back of the chamber. While Weiss Technik test chambers have multiple temperature sensors to help eliminate this, speaking to us about potential risk allows us to make appropriate recommendations to prevent this from happening.

9. Does the product contain explosive materials within it such as solvents or batteries?

Its important for us to know whether batteries or other potentially explosive materials such as solvents are present in your test specimen. Improper testing or over heating of your product could result in an explosion resulting in damage to the chamber and creating a series risk to your employees.

Simultech offers a variety of test chambers suitable for battery and explosive substance testing, however in order to suggest one of these chambers we need to know if the risk exists.

Follow this link to take a look at our products for battery testing.

10. Can hazardous condensate produced by your test?

Is there likely to be hazardous or corrosive condensate generated by your testing, if so then we need to be aware of this in order to make recommendations about the most suitable chamber as well as the best way to eliminate any potential damage to your specimen or the chamber. Weiss Technik test chambers are specially designed to minimize condensate from dripping onto your specimen, by being aware of any possible risk we can make recommendations during installation.

11. What power do you have available?

The majority of our test chambers require 3 phase power, although we do have some chambers suitable for single phase power. Do you have sufficient capacity available for operation of your chamber. For instance a 1500 litre ClimeEvent Test Chamber has a peak power demand of 15 KW.

12. Do you have a fork lift available and have you considered the path the chamber will take from the delivery truck to the test lab?

Typically, Simultech will provide installation and commissioning services with every test chamber delivered. You ou are usually responsible for the unloading and positioning of your new test chamber.

Simultech will provide recommendations around the most suitable forklift to be used, our test chambers can vary in weight from 50 kg to over 3 tonnes.

You should consider the best path that the chamber will follow from the delivery truck to your laboratory. Are there obstacles in the way, such as narrow door ways, steps, rough surfaces etc. These all need to be considered when preparing for unloading and installation of your test chamber.

Simultech believe that by asking your a serious of detailed questions prior to providing a quotation that this will help ensure that you receive the best test chamber for your application.