Understanding heating and cooling rates in an environmental chamber

Heating and cooling rates of change for environmental test chambers may be an important consideration in your test program. Perhaps the standard you are testing to calls for a particular rate or maybe you have lots of cycles to perform when testing your product. So, having confidence in the rate specified on a brochure or Technical Description is essential when deciding which chamber to purchase. Weiss Technik test all of their test chambers to IEC 60068-3-5:2018 "Environmental testing - Part 3-5: Supporting documentation and guidance - Confirmation of the performance of temperature chambers" standard to guarantee that what they list on a brochure is accurate and tested to this internationally recognised standard. This is not always the case for every other chamber manufacturer.

What is the IEC 60068-3-5:2018 Standard?

Amongst other things, the IEC standard specifies the average heating and cooling rates across a temperature range. It is based on a measurement performed between the top and bottom 10% of the temperature range of the test chamber. It is also based on the temperature of the supply air which enters the chamber compartment.

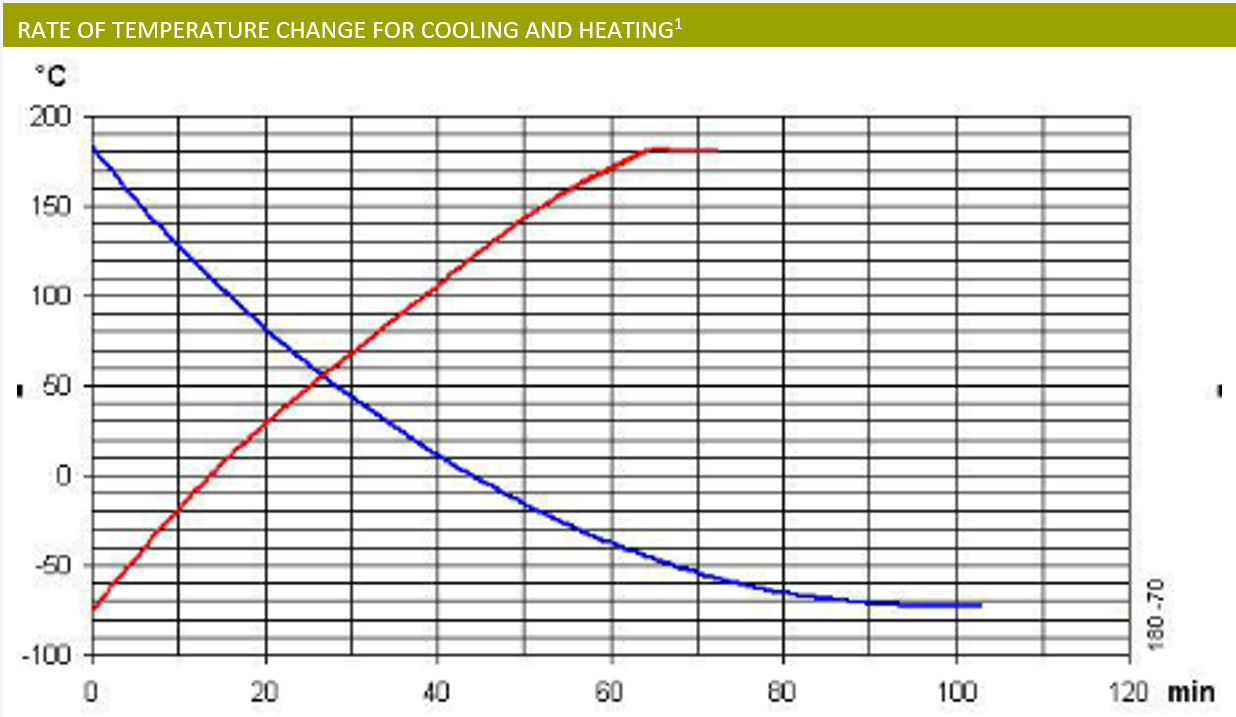

For example, a -40 to 180 deg C test chamber will be tested per the IEC standard from 10% of the total range ie -40 to 180 is 220 deg C so 10% of this range is 22. Therefore, testing is performed between -18 to 158 deg C. For a -70 to 180 deg C chamber the total temperature range is 250, 10% of this is 25 deg C so testing is performed between -45 to 155 deg C.

Typically, once you go beyond the testing thresholds the rate of change will decrease dramatically. Which is why the top and bottom 10% calculation is used.

Graph: Rate of change for Weiss Technik ClimeEvent C/180/70/3 Chamber

Why are heating and cooling rates important?

1. The standard requires a particular rate

Depending on the standard you are testing to it may or may not require a particular rate of change between two temperature set points. If the standard does require a set rate it may be simply specified as a change from -20 to 80 deg C in 10 minutes ie a 10 K/min heating rate.

In this case it’s important to carefully read the standard to identify whether this is referring to the air temperature in the chamber or the actual temperature of your product as this will have a substantial impact. All of Weiss Technik test chambers are based on rate of change of air temperature in the chamber.

However, if your standard requires a temperature change in your product then this significantly complicates the testing. You’ll need to know things such as the size, shape, total volume and materials used in your product. If you can provide this information to us, then we can assist in calculating the actual rate of temperature change that the chamber will require.

For instance, a cubical or spherical specimen with a high weight to volume ratio that is required to heat or cool at 10 K/min may require a 25 K/min chamber. Conversely, a thin flat specimen with minimal weight may successfully be tested in a 10 K/min chamber.

Its also important to recognise that the IEC standard refers to an average rate of change across two temperatures, if you are testing in a narrower temperature range than the actual rate of change achieved by the chamber may be higher than that specified.

For instance in a -40 to 180 deg C chamber the rate of change for heating might be 10 K/min between -18 to 158 deg C, yet across 0-80 deg C it may be as high as 12 or even 15 K/min. Thus, allowing you to achieve the desired heating or cooling rate without buying a faster more expensive chamber.

2. You have lots of test cycles to perform.

Some testing and test standards may call for thousands of cycles between two temperature setpoints ie 3500 cycles between 0 to 50 deg C or 2,000 cycles between -30 to 100 deg C as an example. No time limit may be specified so the faster your chamber cycles between its test points the faster you can complete the test. There is obviously a cost to benefit relationship as a fast chamber is going to cost significantly more and may not be worth the extra cost.

An interesting situation arises when testing as an example from -30 to 100 deg C. If you use a -40 to 180 deg C 3 K/min chamber, then 10% of the IEC range is -18 to 158 deg C, so once you drop below -18 deg C, the chamber will no longer cool at a 3 K/min rate and may even decrease to as low as 0.5 K/min depending on the chamber. Thus, it can take a long time to cool to -30 deg C and will have a significant impact on the time your testing will take.

But if you were to instead use a -70 to 180 deg C 3 K/min chamber then the temperature change rate is valid from -55 to 155 deg C and so although you may never need to go below -30 deg C, your testing can be performed in a significantly faster time.

In this article we have tried to explain the importance of understanding what the IEC standard is and how it relates to the chambers specifications as well as the impact that it can have on your testing program. Understanding this when purchasing a chamber that you will use for 10-20 years is important as it can have a significant impact on the cost of producing and testing your product. The Simultech team believe that our customers should purchase the right product both for testing today and testing into the future. We want our customers to be happy with their purchase and to have considered all the critical aspects of our chambers. Its our 20 years of local experience that enables us to help you make the right decision.